Industries

|

|

|

Machine Tools

|

|

| CNC Design offers comprehensive support for Machine Tools in our region |

| As the exclusive distributor for Siemens SINUMERIK CNCs in our region and with 30+ years’ experience with Siemens products our support includes: |

- OEMs: Sales & support for SINUMERIK CNCs.

- Retrofit: Turnkey integration of SINUMERIK CNCs including mechanical overhaul when required.

- Spare Parts: Local stock of spare parts for both current & previous generation of SINUMERIK CNCs.

- Training: We provide training for engineering, operations & maintenance. Courses can be done either on-site or at CNC Design’s offices and tailored to meet your requirements.

|

|

| The company was established in 1984 as a machine tool retrofit company, and this remains the core of our business. With Siemens CNCs we can tackle any project in any technology from traditional milling & turning, to multitasking, through to 3D printing & additive manufacturing. |

|

|

|

|

|

Aerospace

|

|

| The aerospace industry has always been a driver for CNC technology |

From the time of John T.Parsons and the development of Numerical Control (NC) in the 1950s to today’s CNC machines, aerospace applications have been at the leading edge of technological development.

Around the world, at leading prime commercial & military aircraft manufacturers plus engine manufacturers, SINUMERIK CNCs can be found doing the most complex & demanding applications.

And increasingly the use of industrial robots can be found being controlled by SINUMERK CNCs, and this is complemented by functions such as Run MyRobot / Direct Control.

Examples of functions of SINUMERIK CNCs used in aerospace include: |

|

- 5, 6 & 7 Axis Machining

- High Speed Machining with Advanced Surface & Top Surface

- Volumetric Compensation

- Run MyRobot / Direct Control

- NCU Link for up to 93 Axes on 1 CNC

- NCK Open Architecture (Compiled Cycles)

- HMI Open Architecture

|

|

|

|

|

|

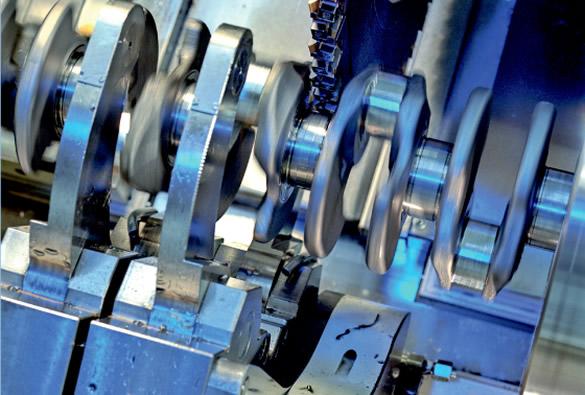

Automotive

|

|

| From discrete machine tools to complete transfer line retrofits for manufacturing engines and power transmission components to large press retrofits for automotive body manufacturing |

CNC Design has acquired invaluable experience in this industry during the many years of experience working with local & overseas car manufacturers.

While car production in Australia has ceased there remain local applications in design centres.

And in SE Asia there remains a strong automotive industry and with our Thailand facility we have the expertise & capacity to handle large scale upgrade & modernisation projects.

Other than the mainstream powertrain business, our team have working together with our local machine tool builders & end-users for manufacturing special purpose machinery, e.g. gear box testers, hot & cold engine test stands, fatigue testing & chassis rail drilling for the truck industry. |

|

|

|

|

|

|

|

|

Rail

|

|

| Rail has been and remains critical to Australia, both city metro systems & transportation of goods across the country and for the mining industry |

CNC Design’s focus for rail is maintenance, specifically wheel lathes. Portal / Above Floor Wheel Lathes (with wheel set removed from the bogie) & Under Floor Wheel Lathes (with wheel set in situ on the bogie & train) are a key to all rail workshops.

We have been involved with both OEMs and for the upgrade & modernisation of these machines for more than 20 years.

Besides machine tools the automation of modern rail workshops means that handling has become an important topic. CNC Design is able to accomplish this task with Gudel gantries and Siemens Motion Control products, SINUMERIK or SIMATIC. |

|

|

|

|

|

Steel & Paper

|

|

| CNC Design has extensive experience in the steel industry for both machine tool & process lines |

| Machine Tools |

| |

| The focus for machine tools is our ROLLGrind package for the electrical & mechanical upgrade of roll grinders found in steel mill roll shops around the world. |

|

| Besides roll grinders we have completed many projects for roll lathes. |

| |

| Coating Lines |

|

| CNC Design works very closely with companies, such as Bronx, to supply complete automation system in projects related to steel processing lines, e.g. coating, galvanising & painting, and also sub-systems, e.g. tension levellers. |

|

|

|

|

|

Materials Handling

|

|

| Safety & productivity are key topics for all businesses |

Large area gantries are commonplace in the logistics & warehousing markets, and with CNC Design representing Güdel in our region, we can provide the necessary expertise to support this market.

Another market where handling can be applied to improve safety & productivity is the building material industry, e.g. handling of large purlins and sheet steel products. These products are often heavy and difficult to manage manually or with cranes & other manually operated lifting equipment.

Güdel ZP & FP gantries and Siemens Motion Control, SINUMERIK or SIMATIC, can provide a solution to most handling applications. With payload capacity up to 3,000kg and large area coverage a wide range of applications is possible. |

|

|

|

|

|

|

|